How is glaze ceramic produced?

31/07/2025

Overview

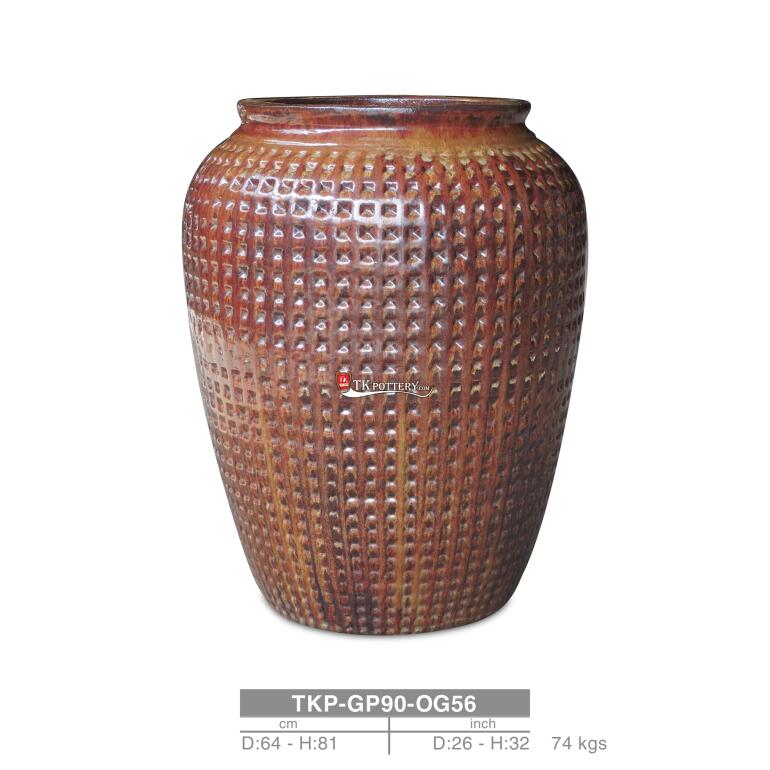

Our Outdoor Glazed Ceramic Collection is the perfect blend of vivid color and durable craftsmanship. Designed for open-air living, each piece is handmade using traditional techniques and finished with beautiful, weather-resistant glazes. These ceramics are built to last — from sunny gardens to cold winters.

Key Features

· Colorful & Glossy Finish: A wide variety of glaze tones to complement outdoor décor.

· Traditional Craftsmanship: Handmade using natural clay and wood-fired kilns.

· Durability: Frost-proof and resistant to cracking in all climates.

Material & Craftsmanship

· Clay Preparation: A carefully balanced mixture of white, red, yellow, and grey clays is soaked in water for 24 hours, then blended and ground to achieve a fine, plastic consistency.

· Molding: Clay is cut into 10–13 mm thick slabs and formed in plaster molds. Each piece is matured indoors for 6 to 24 hours, then sun-dried for 3–6 days under natural heat.

· Glazing & Firing:

o Once dried, pots are coated with glaze and fired in wood kilns at 1150–1200°C

o The firing process takes 5 days, followed by 2 days of cooling to ensure maximum durability