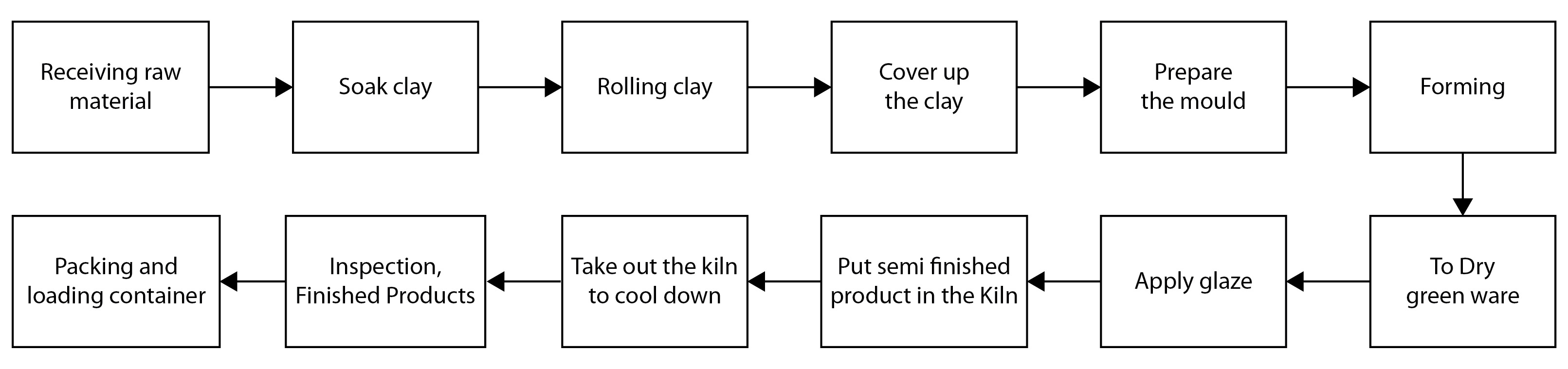

PRODUCTION PROCESSING

I. PRODUCTION PROCESSING, QUALITY INSPECTION PROCEDURES.

Processing is as follows:

| SEQ | Description | Performer | Contactor |

|---|---|---|---|

| Receiving raw material | - In practical experience, the receipt and evaluation of soil quality was performed by looking, taste, touch ... - For all types of clay may be accurately determined, it should produce test samples for quality testing before putting the land into production |

- Production Manager | - Director - Supplier |

| Soak clay | Purpose: Alum and filtered to remove impurities and large particles in the clay | - The workers |

- Production manager |

| Rolling and cover up the clay | After being soaked and filtered of impurities, the clay was put into the mill to prepare materials for the production. Cover up to increase the viscosity of the clay, easily to forming | - Production manager - The worker |

Factory manager |

| Prepare the Mould | The mould have to be cast in the form of the design department. If the products is the new samples, Design department have to send the artwork to the worker who make the mould and after the mould is finished It has to be approval by design department before use for forming | - Design Department - The Worker |

Sales Department |

| Forming | Performed using turntables or presses or formed by the mould was cast in the form of the design department. Products formed by the two methods can: pour or squeeze up. after shaping, workers need to check, edit, complete product lines, patterns and eliminate excess seats. | - The worker | - Factory manager - Production manager |

| To dry the greenware | Purpose: - Time to burn the products is shorten - Check products to remove the broken product, distortion product,.ect |

- The worker | - Factory manager - Production manager |

| Apply glaze | Semi-finished products are applied the glazes. | - The worker | - Factory manager - Production manager |

| Put Semi-finished products into the Kiln | Put products into the Kiln | - The worker - Production manager |

- Factory manager |

| Take out the Kiln to cool down and Finished products | - After burning, take the products out of the Kiln, do preliminary inspection, finishing products and transport to ware house. | - Factory manager - Production manager - The worker |

- Managing Director - Factory manager |

| Inspection, packing before loading container | - When the products transport to warehouse, the QC team have to inspect the quality (based on the quality guide line) to reject the non-qualify products as P.O requirement.. - Do packaging and loading on container |

- QC team | Sales Department |

II.QUALITY INSPECTION GUIDELINES

The objective of this quality manual is to promote a clear understanding of quality control of TKpottery. This manual contains a basic format that lays the foundation for an effective quality assurance system and introduces the inspection criteria.

The guidelines in this manual are restricted to both indoor and outdoor ceramic potteries.

RAW MATERIAL :

The Produtcion manager will do in-house checking the raw materials (clay and glazes) before put in mass production .

Production manager and QA will inspect, assess quality of clay and glaze by practical experiences such as: bonded, touch.. This is the perceptible assessment. If need, Production manager can assess by making the samples to test the quality of clay and glaze..

PRODUCTS :

1. Quality control during production

The QA team will do inline checking during the mass production every week. If he can detect some defects, he have to inform production manager and find a corrective action.

This inspection will control 100% of semi-finished products.

2 . Quality control after finishing production:

When the products come out the Kiln and transport to warehouse. The QC at ware house have to inspect before packing and loading container.

This inspection will control 100% of finished products., and based on classification as follows:

1. CLASSIFICATION OF DEFECTS

Defects are classified into three categories:

(a) ‘Critical’ defect: A defect that fails to meet mandatory regulation and/or affects the safety of consumers when using the product.

(b) ‘Major’ defect: A defect that affects the sale ability or the product’s design or the used materials, colors etc are not same as the approved sample.

(c) ‘Minor’ defect: A defect that is marginal or do not affect the sale ability but has a discrepancy from the defined quality standard.

2. INSPECTION CRITERIA

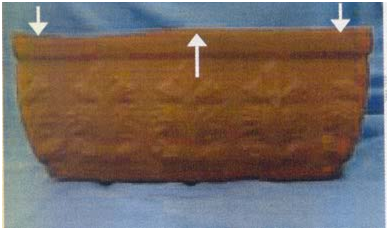

2.1. Clay body

Any chips or cracks on the body are not acceptable (rated as ‘major’ defect).

2.2. Glaze

- Indoor ceramics without glazed, both inside and/or outside (except outside base), are considered ‘major’ defect.

- Blistering and crawling are not acceptable on glaze surface (rated as ‘major’ defect).

- The glaze must be covered from the ‘bottom edge’ to ‘under rim’.

2.3. Dimensions and shapes

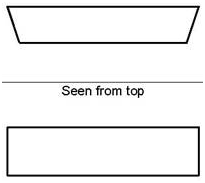

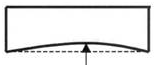

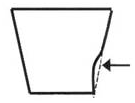

Table 1 and Table 2 show the acceptable and non-acceptable dimensions and shapes of pots.

Table 1: Acceptable dimension

| Criteria | See examples | Applicable for | Deviation allowed (maximum) | |

|---|---|---|---|---|

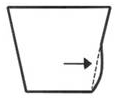

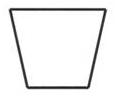

| 1 | Height | Image 1 | All kinds of products (including animals) | +/- 5% |

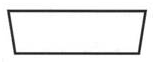

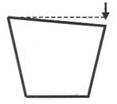

| 2 | Diameter (outer – maximum) | Image 2 | +/- 5% | |

| 3 | Length and width | Rectangular products | +/- 5% | |

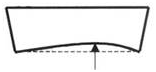

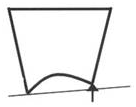

| 4 | Rectangularity of edges | Image 3 | Rectangular products | +/- 3% |

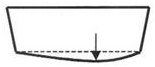

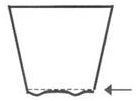

| 5 | Straightness of edge | Image 4 | Rectangular products | +/- 2% |

| 6 | Regular shape of surface deviation / height | Image 1 | All kind of products | +/- 2% |

| 7 | Upright stand deviation / diameter | Image 2 | All kind of products with flat base / animals | +/- 2% |

Image 1

Height  Irregular shape of surface

Irregular shape of surface

Image 2

Upright stand

Upright stand

Image 3

Image 4

Table 2: Types of defects in shapes

|

Preferred |

Major defect |

|

|

Straightness of the edges |

||

|

Side view |

|

|

|

Seen from top |

|

|

|

Regular shape of surfaces |

||

|

|

|

|

|

|

|

|

|

Upright stand, no wobbling |

||

|

|

|

|

|

|

|

|

2.4. Chips and other effects

Table 3 and Table 4 show the acceptable and non-acceptable levels of chips and other effects (pinhole, pinheads and blister).

Table 3: Chips

| Type of pot | Preferred | Minor defect | Major defect |

|---|---|---|---|

| Pot height < 30 cm | No chips, no flakes | Maximum diameter < 0.3 cm (only one single defect) | Maximum diameter > 0.5 cm or several small defects |

| Pot height > 30 cm | No chips, no flakes | Maximum diameter < 0.5 cm (only one single defect) | Maximum diameter > 0.8 cm or several small defects |

Table 4: Pinholes, Pinheads and Blisters

| Type of failure | Preferred | Minor defect | Major defect |

|---|---|---|---|

| Pinhole / grain diameter < 1mm | No flaw | 5 or lesser flaws on the surface | More than 5 flaws on the surface |

| Pinhole / grain diameter > 1 mm | No flaw | Any pinhole and grain | |

| Blister | No blister | Any blister |

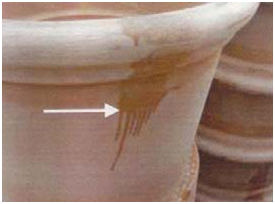

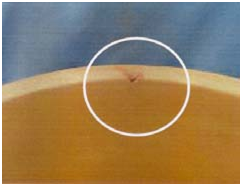

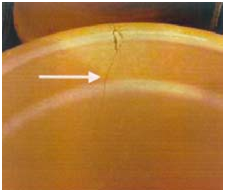

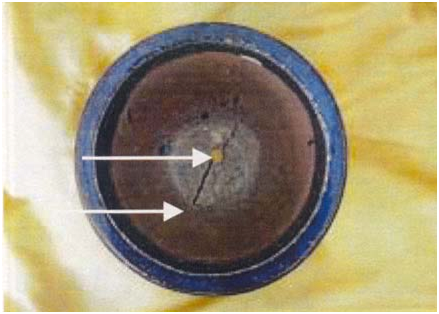

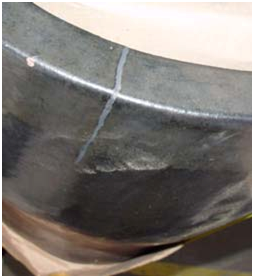

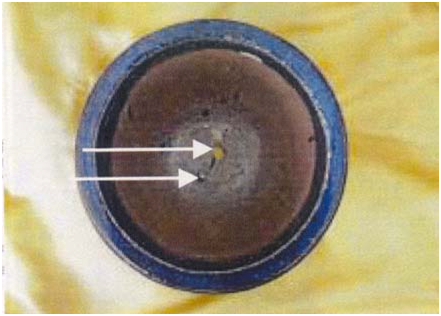

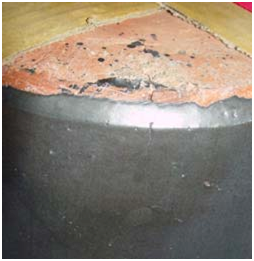

2.5. Crazing

Crazing is not acceptable (rated as ‘major’ defect – see image belows)

2.6. Colors

Colors are checked based on the approved samples (shards and fragments of pottery) with the agreed color variation. Non-conformity of color is rated as 'major' defect.

2.7. Drainage holes

Drainage holes will be required depend on each customer... Production manager and QC have to check carefully on each order.

Some defects:

| Description | Image | Type of defect |

|---|---|---|

| Big chip on the bottom |  |

Major |

| Surface not equable |  |

Major |

| Efflorescence on the surface |   |

Major |

| Rim not straight |   |

See table 2 |

| Hole on the rim |   |

Major |

| Crack on the clay body |   |

Major |

| Different colour on the same article. |   |

Major |

| Glazed less point on the rim |   |

Major |

| Crack on the bottom |   |

Minor |

| Chips bigger than 0.8 cm on the rim |   |

Major |

| Pot is not round |   |

Major |

| Crack in the clay body |   |

Major |

| Rim is defective |   |

Major |

| Crack on the base |   |

Major |

| Chip on the clay body but the glaze is well and closed |   |

Major |

| One small crack on the bottom rim |   |

Minor |

| Glazed rim inside are not even |   |

Minor |

| Glazed rim on the bottom are not even |   |

Minor |

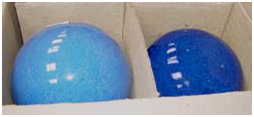

3. PACKAGING

Packaging materials used must be able to support and protect the products. Depend on each customer’s requirement, the packaging maybe different. However, In general, the pallet and packing must be as follows:

- The pallet should not exposed to rain or stored outdoors or placed on wet ground

- Maximum height inclusive of pallet is 225 cm for container DC, 255 cm for container HC

- Pallet must not be damaged or craked.

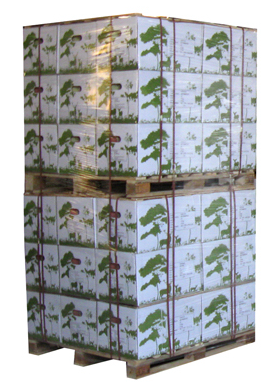

3.1. With indoor products: The products have to be packed by carton box then put on pallet and secured with plastic straps. See picture belows:

|

|

|

3.2. With Outdoor products: The products have to be packed by carton bundle then put on pallet and secured with plastic straps. There is a wooden frame between each layer. Some products have to be packed by wooden –crate.

|

|

|

THIEN KY EXIM CO., LTD (TKPOTTERY.COM)

Not acceptable if pot is wobbling

Not acceptable if pot is wobbling